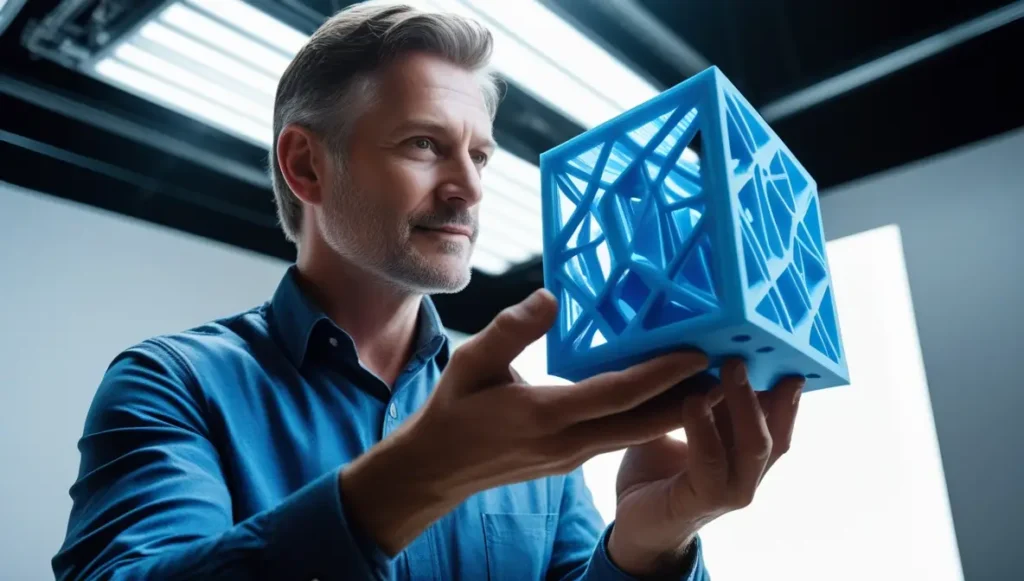

3D printing has become an increasingly accessible and fascinating hobby, especially for men in their early 50s who are looking to explore new creative outlets or dive into the world of technology. Whether you’re a beginner or have some experience with digital design, understanding the tools required for 3D printing is essential to ensure a smooth and enjoyable journey. In this article, we’ll break down everything you need to know about the tools necessary for successful 3D printing while keeping the content engaging and easy to follow.

Understanding the Basics: What Exactly Is 3D Printing?

Before diving into the tools, it’s important to understand what 3D printing entails. At its core, 3D printing is the process of creating three-dimensional objects from a digital file. This technology allows users to bring their ideas to life layer by layer, using materials like plastic, resin, or even metal. For a man in his early 50s, this could mean anything from designing custom parts for home projects to creating intricate models as a hobby.

“3D printing empowers creativity and innovation, offering endless possibilities for those willing to learn and experiment.” – Industry Expert

With that in mind, let’s explore the essential tools you’ll need to get started.

The Core Hardware: Your 3D Printer

The most obvious tool you’ll need is the 3D printer itself. There are several types of printers available on the market, each catering to different needs and budgets. Here’s a quick breakdown:

Types of 3D Printers

| Type | Best For | Pros | Cons |

|---|---|---|---|

| FDM (Fused Deposition Modeling) | Beginners and hobbyists | Affordable, easy to use, wide material options | Lower resolution compared to other types |

| SLA (Stereolithography) | High-detail projects | Exceptional detail, smooth finishes | Expensive, limited material options |

| SLS (Selective Laser Sintering) | Industrial applications | Strong parts, no support structures needed | Very costly, complex setup |

For most men in their early 50s starting out, an FDM printer is often the best choice due to its affordability and ease of use. Once you’ve chosen your printer, there are additional tools you’ll need to make the process seamless.

Software Tools: From Design to Execution

While the printer is the heart of your setup, software plays a crucial role in bringing your ideas to life. Here are the key software tools you’ll need:

CAD Software for Designing Models

CAD (Computer-Aided Design) software allows you to create your own 3D models. Some popular options include:

- TinkerCAD : Perfect for beginners due to its user-friendly interface.

- Fusion 360 : Ideal for more advanced users who want professional-grade tools.

- Blender : Great for artistic designs and sculpting.

If you’re not ready to design your own models, platforms like Thingiverse offer thousands of free downloadable designs.

Slicing Software for Preparing Prints

Once your model is ready, you’ll need slicing software to convert it into instructions your printer can understand. Popular choices include:

- Cura : Free, open-source, and compatible with most printers.

- PrusaSlicer : Known for its advanced features and high-quality results.

- Simplify3D : A premium option with extensive customization capabilities.

These tools allow you to adjust settings like layer height, infill density, and print speed to optimize your prints.

Essential Accessories and Tools for Maintenance

To keep your 3D printing experience hassle-free, having the right accessories and maintenance tools is crucial. Let’s take a look at some must-haves:

Cleaning and Calibration Tools

- Digital Calipers : For precise measurements of your prints.

- Nozzle Cleaning Kit : To remove clogs and ensure smooth filament flow.

- Bed Leveling Tool : Ensures your print bed is perfectly aligned.

Safety Gear

- Heat-Resistant Gloves : Protect your hands when handling hot components.

- Safety Goggles : Shield your eyes during maintenance tasks.

Storage Solutions

Filament storage is often overlooked but incredibly important. Moisture can ruin filament, so investing in airtight containers or desiccant packs is highly recommended.

“Proper maintenance and organization are key to consistent, high-quality prints.”

Choosing the Right Materials: Filaments and Beyond

The material you choose will significantly impact the quality and durability of your prints. Here’s a list of common filaments and their uses:

- PLA (Polylactic Acid) : Beginner-friendly, biodegradable, and ideal for prototypes.

- ABS (Acrylonitrile Butadiene Styrene) : Strong and durable, suitable for functional parts.

- PETG (Polyethylene Terephthalate Glycol) : Combines the ease of PLA with the strength of ABS.

- TPU (Thermoplastic Polyurethane) : Flexible material great for phone cases or gaskets.

For a man in his early 50s working on household projects, PLA and PETG are excellent starting points due to their balance of usability and performance.

Troubleshooting Common Issues

Even with the best tools, challenges can arise during 3D printing. Here are some common problems and how to address them:

- Warping : Ensure your print bed is clean and properly leveled.

- Stringing : Adjust retraction settings in your slicing software.

- Layer Shifting : Check that belts and pulleys are tight and functioning correctly.

By familiarizing yourself with these issues, you’ll be better equipped to handle setbacks and improve your skills over time.

Expanding Your Toolkit: Advanced Tools for Enthusiasts

As you grow more comfortable with 3D printing, you may want to expand your toolkit. Consider adding these advanced tools:

- Dual Extruder Upgrade : Allows multi-material or multi-color prints.

- Enclosure : Regulates temperature for better print consistency.

- Laser Engraver Attachment : Adds versatility to your printer.

These upgrades can elevate your projects and open up new creative possibilities.

Frequently Asked Questions (FAQ)

Q: How much does it cost to start 3D printing?

A: Entry-level FDM printers typically range from $200 to $500, with additional costs for filament and accessories.

Q: Do I need technical skills to use a 3D printer?

A: While basic technical knowledge helps, many modern printers are designed to be user-friendly for beginners.

Q: Can I repair my own 3D printer if something breaks?

A: Yes, most issues can be resolved with troubleshooting guides and basic tools, though some repairs may require professional assistance.

Conclusion: Embrace the World of 3D Printing

For a man in his early 50s, 3D printing offers a unique blend of creativity, problem-solving, and technological exploration. By equipping yourself with the right tools—from hardware and software to maintenance gear—you can unlock endless possibilities. Remember, the journey doesn’t stop at acquiring tools; continuous learning and experimentation are what truly make 3D printing rewarding.

Now that you’re armed with the knowledge of what tools you need, why not take the plunge? Start small, stay curious, and watch as your ideas transform into tangible creations.